Adjustable Speed and Stitch Length Control

One of the most common features with which mattress flanging machines can be customized is the adjustable speed and stitch length control. Different mattress types require different settings for optimal results. Heavy-duty mattresses may need slower speeds with longer stitches, while luxury mattresses benefit from shorter, more delicate stitches.

This customization allows manufacturers to achieve greater precision and flexibility, tailoring each mattress to specific quality standards. The control panel allows operators to set parameters like stitch length and speed, enabling quick transitions between different mattress types while minimizing downtime.

Material Compatibility and Needle Options

Modern mattress manufacturing involves various materials from traditional fabrics to innovative foams. Flanging machines can be equipped with different needle options to handle these materials effectively. Heavy-duty needles work with thick or multi-layered materials, while specialty needles suit lighter fabrics.

Some machines can be adjusted to process specialty materials with high elasticity or specific thicknesses. This versatility is crucial for manufacturers producing diverse product lines.

Programmable Stitch Patterns and Automation

Advanced flanging machines offer computerized controls allowing for customized stitching patterns, ensuring consistent results across the entire mattress. These programmable features allow manufacturers to preload stitch patterns, providing uniform stitching with minimal human input.

Full automation in these machines can significantly reduce labor costs while increasing production speeds. Systems can be customized to automatically adjust tension, speed, and pattern based on the mattress type being produced.

Edge Trimming and Binding Features

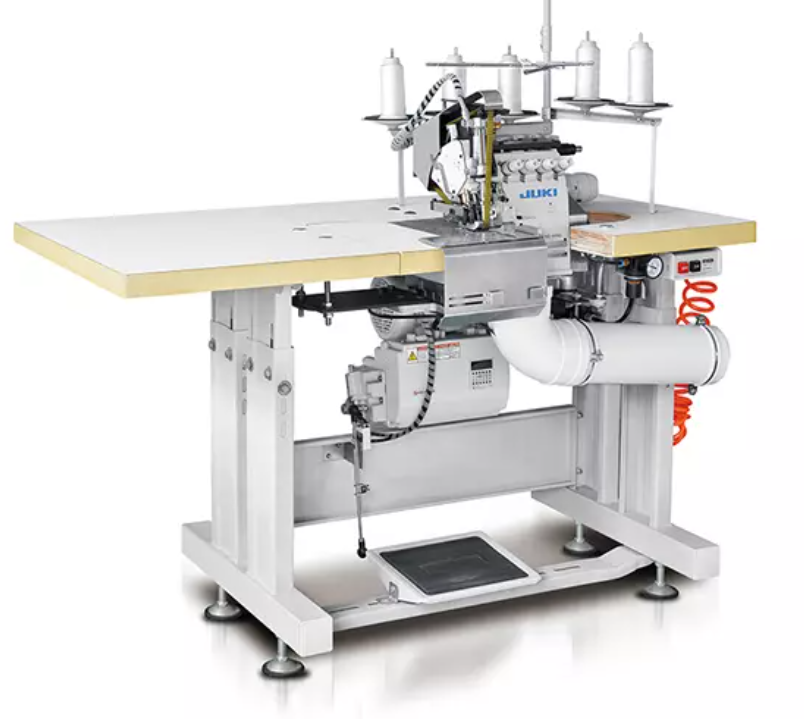

Many flanging machines include edge trimming and binding features that automate the finishing process. The VFM-4516 trims panel edges, overlocks, and adds a safety stitch, creating a clean, professional appearance that’s particularly important for high-end mattresses.

Binding features protect edges from fraying, enhancing durability. Automating these processes increases production speed while ensuring consistent quality.

Flexible Frame Sizes and Adjustability

Modern flanging machines can be customized with adjustable frames to accommodate different mattress dimensions. This flexibility allows manufacturers to switch between various sizes without investing in separate machines for each size.

With stacking speeds reaching 200 pieces per hour and maximum stackable heights of 1800mm, these adjustable frames enhance versatility and efficiency.

Enhanced Ergonomics and Operator Controls

While automation is important, human operators remain essential. Machines can be customized with ergonomic features like adjustable height settings and intuitive control panels for operator comfort and efficiency. Some systems offer full-automatic or separate axle control options with high-precision pattern sewing capabilities.

These ergonomic enhancements reduce operator fatigue and minimize errors, resulting in higher overall efficiency and product quality.>>>learn more